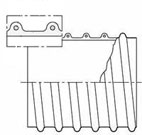

Hose of pure polyurethane with steel wire helix cast firmly integral in hose wall. Hose profile with optimum shape of flow giving optimum flow properties and high internal smoothness. Wall thickness approx. 1,5 mm

Extremely abrasion proof. Flexible and kink-proof also at low temperatures. Microbe and hydrolysis resistant. Resistant to tension and tearing and to mechanical stress. Good resistance to oil, fuel vapors and other chemicals.

extremely abrasion proof.

During spring and summer 2014, as items on stock are turned around, the material in these hoses will be upgraded to a permanently antistatic version of polyurethane with a surface resistance of 10EXP9 Ohm.

Hoses with the antistatic material will be marked "...AS permanent antistatic 10E9 Ohm".

Extremely abrasion proof suction and blast hose, especially suitable for

the application with foodstuffs

- for high weight rate of flow of high abrasive solids as coarse and sharp-edged granulated materials

- for aggressive gaseous and l

| Temperature Area | Approx. -40 °C to approx. +90 °C For short periods up to approx. +125 °C |

| Colour | Natural |

| Standard Length | 10 m |

| Dimension Range | 13-500 mm |

Following material performance are available:

1a. Food quality approved performance/hydrolysis constant. Ether based PUR material which complies with FDA directive 21 CFR 177.2600 and 178.2010. The complete hose complies with EC guideline 2002/72/EC (earlier 90/128/EEC) Exellent resistance to micro organisms. Specially suitable when handling victuals.

Can be electrostatic discharge by grounding the helix.

1b. Food quality approved performance. Same as in 1a, but where also the metal spiral is in stainless steel performance.

2. Hosewall in ether-based polyurethane in flame-retardant performance. Tested accordingly to UL 94-V2, DIN 4102-B1, DIN 5510 part 2 (S2-S4, SR2, ST2)

3. Hosewall in antistatic ester-based polyurethane. Colour: black. Resistance hosewall

For more information

| Item No | ID [mm] | OD [mm] | Bending radius [mm] | Working Pressure [kPa] | Vacuum [kPa] | Weight [g/m] |

| 263013 | 13 | 20 | 20 | 450,0 | 100,0 | 140 |

| 263016 | 16 | 23 | 23 | 430,0 | 100,0 | 160 |

| 263020 | 20 | 27 | 27 | 410,0 | 100,0 | 230 |

| 263025 | 25 | 32 | 32 | 365,5 | 100,0 | 280 |

| 263030 | 30 | 40 | 40 | 345,0 | 98,0 | 420 |

| 263032 | 32 | 42 | 42 | 326,0 | 97,0 | 440 |

| 263035 | 35 | 45 | 45 | 311,0 | 97,0 | 480 |

| 263038 | 38 | 48 | 48 | 308,0 | 95,0 | 520 |

| 263040 | 40 | 50 | 50 | 305,0 | 95,0 | 540 |

| 263042 | 42 | 52 | 52 | 291,0 | 94,0 | 600 |

| 263045 | 45 | 55 | 55 | 273,0 | 94,0 | 660 |

| 263050 | 50 | 60 | 60 | 245,0 | 93,0 | 660 |

| 263055 | 55 | 65 | 65 | 225,0 | 88,0 | 780 |

| 263060 | 60 | 70 | 70 | 206,0 | 81,0 | 840 |

| 263065 | 65 | 75 | 75 | 191,0 | 75,0 | 980 |

| 263570 | 70 | 81 | 97 | 178,0 | 67,0 | 1110 |

| 263075 | 75 | 86 | 103 | 166,0 | 61,5 | 1240 |

| 263080 | 80 | 91 | 109 | 156,0 | 56,0 | 1110 |

| 263090 | 90 | 101 | 121 | 130,0 | 42,5 | 1240 |

| 263100 | 100 | 111 | 133 | 125,0 | 39,0 | 1470 |

| 263102 | 102 | 113 | 136 | 122,5 | 39,0 | 1510 |

| 263110 | 110 | 121 | 145 | 114,0 | 36,0 | 1610 |

| 263115 | 115 | 126 | 151 | 109,0 | 33,5 | 1680 |

| 263120 | 120 | 131 | 157 | 105,0 | 31,5 | 1750 |

| 263125 | 125 | 136 | 163 | 101,0 | 29,5 | 1820 |

| 263130 | 130 | 141 | 169 | 96,5 | 27,9 | 1890 |

| 262140 | 140 | 151 | 181 | 90,0 | 24,0 | 2030 |

| 262150 | 150 | 161 | 193 | 84,0 | 20 | 2380 |

| 263152 | 152 | 163 | 196 | 82,5 | 19,5 | 2440 |

| 263160 | 160 | 171 | 205 | 78,5 | 18,5 | 2530 |

| 263170 | 170 | 181 | 217 | 74,0 | 17,0 | 2720 |

| 263175 | 175 | 186 | 223 | 72,0 | 15,5 | 2770 |

| 263180 | 180 | 191 | 229 | 70,0 | 15,0 | 2840 |

| 263200 | 200 | 213 | 256 | 63,0 | 13,5 | 3090 |

| 263215 | 215 | 228 | 274 | 59,0 | 12,0 | 3310 |

| 263225 | 225 | 238 | 286 | 56,0 | 11,0 | 3460 |

| 263250 | 250 | 263 | 316 | 51,0 | 8,5 | 3840 |

| 263275 | 275 | 288 | 346 | 46,0 | 8,0 | 3840 |

| 263280 | 280 | 293 | 352 | 45,0 | 7,5 | 4290 |

| 263300 | 300 | 313 | 376 | 42,0 | 7,0 | 5160 |

| 263320 | 320 | 333 | 400 | 39,5 | 6,5 | 5440 |

| 263325 | 325 | 338 | 406 | 38,5 | 6,5 | 5530 |

| 263350 | 350 | 363 | 436 | 36,0 | 5,5 | 5940 |

| 263375 | 375 | 388 | 466 | 34,0 | 5,0 | 6360 |

| 263400 | 400 | 413 | 496 | 32,0 | 4,5 | 6780 |

| 263450 | 450 | 463 | 556 | 28,0 | 3,5 | 7610 |

| 263500 | 500 | 514 | 617 | 25,5 | 3,0 | 8450 |

Updated 2018-01-02