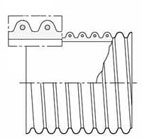

Very robust polyurethane hose with embedded, strong, tightly-wound spring steel helix, diam. 1.5-3.0 mm. The inside of the hose is smooth and the material is 2.0 – 2.5 mm thick, so it can handle mechanical stresses. Can be electrostatically discharged in accordance with BGR132 (formerly ZH 1/200) by earthing the helix.

Flexible, heavy-duty hose with axial stability and excellent abrasion resistance. Excellent tensile strength, elongation and tear resistance. Resistant to oil, petrol and acid. UV- and ozone-resistant.

During spring and summer 2014, as items on stock are turned around, the material in these hoses will be upgraded to a permanently antistatic version of polyurethane with a surface resistance of 10EXP9 Ohm.

Hoses with the antistatic material will be marked "...AS permanent antistatic 10E9 Ohm".

Vacuum extraction and transport of abrasive materials with high vacuum or high pressure. Suitable for materials that require tear-resistance and resistance to chemicals.

| Temperature Area | Continuously -40 °C to +90 °C, with dry air Intermittently -40 °C to +125 °C, with dry air |

| Colour | Naturally transparent |

| Standard Length | 10 m |

| Dimension Range | 32-300 mm |

1a. Food grade version / resistant to hydrolysis. Ether-based PUR material complies with FDA Directives 21 CFR 177.2600 and 178.2010.2600 and 178.2010. The entire hose complies with Directive 2002/72/EC (formerly 90/128/EEC).Very good resistance to micro-organisms. Particularly suitable for handling foodstuffs.

1b. Food grade version. As 1a but with helix of stainless steel.

2. Hose wall of antistatic ester-based polyurethane. Colour: black. Surface resistance of hose wall < 1 kohm. Complies with the requirements of the ATEX guidelines.

For more information

| Item No | ID [mm] | OD [mm] | Bending radius [mm] | Working Pressure [kPa] | Vacuum [kPa] | Weight [g/m] |

| 264032 | 32 | 43 | 116 | 515,0 | 100,0 | 680 |

| 264038 | 38 | 49 | 132 | 438,0 | 100,0 | 790 |

| 264040 | 40 | 51 | 138 | 417,0 | 100,0 | 820 |

| 264050 | 50 | 61 | 165 | 365,0 | 100,0 | 100 |

| 264055 | 55 | 66 | 178 | 342,0 | 100,0 | 1090 |

| 264060 | 60 | 71 | 192 | 315,0 | 100,0 | 1180 |

| 264063 | 63 | 74 | 199 | 302,0 | 100,0 | 1230 |

| 264065 | 65 | 76 | 205 | 291,0 | 100,0 | 1270 |

| 264070 | 70 | 82 | 221 | 271,0 | 100,0 | 1370 |

| 264075 | 75 | 87 | 235 | 254,0 | 100,0 | 1460 |

| 264080 | 80 | 92 | 249 | 238,0 | 100,0 | 1550 |

| 264090 | 90 | 103 | 309 | 212,0 | 100,0 | 2060 |

| 264100 | 100 | 113 | 339 | 191,0 | 100,0 | 2270 |

| 264102 | 102 | 115 | 345 | 188,0 | 100,0 | 2310 |

| 264110 | 110 | 123 | 369 | 174,0 | 98,5 | 2480 |

| 264115 | 115 | 128 | 384 | 167,0 | 96,0 | 2580 |

| 264120 | 120 | 133 | 399 | 160,0 | 93,5 | 2690 |

| 264125 | 125 | 138 | 414 | 154,0 | 90,0 | 2800 |

| 264127 | 127 | 140 | 420 | 151,0 | 89,0 | 2840 |

| 264130 | 130 | 143 | 429 | 148,0 | 86,5 | 2900 |

| 264140 | 140 | 153 | 459 | 137,5 | 84,0 | 3110 |

| 264150 | 150 | 163 | 489 | 128,0 | 84,0 | 3680 |

| 264152 | 152 | 165 | 495 | 127,0 | 83,5 | 3720 |

| 264160 | 160 | 173 | 519 | 121,0 | 80,5 | 3910 |

| 264175 | 175 | 188 | 658 | 110,5 | 75,5 | 4260 |

| 264180 | 180 | 193 | 676 | 107,0 | 74,0 | 4380 |

| 264200 | 200 | 214 | 835 | 97,0 | 66,0 | 4860 |

| 264225 | 225 | 239 | 932 | 86,0 | 56,5 | 5450 |

| 264250 | 250 | 264 | 1450 | 78,0 | 41,0 | 6040 |

| 264275 | 275 | 289 | 1590 | 70,5 | 27,5 | 6620 |

| 262300 | 300 | 314 | 1725 | 65,0 | 21,5 | 7210 |

Updated 2018-01-02